Steam Spraying Technology: Steam Replaces Atomizing Air

- Water vapour as atomizer medium

- Especially fine material atomization

- Suitable for water-based materials

Contents

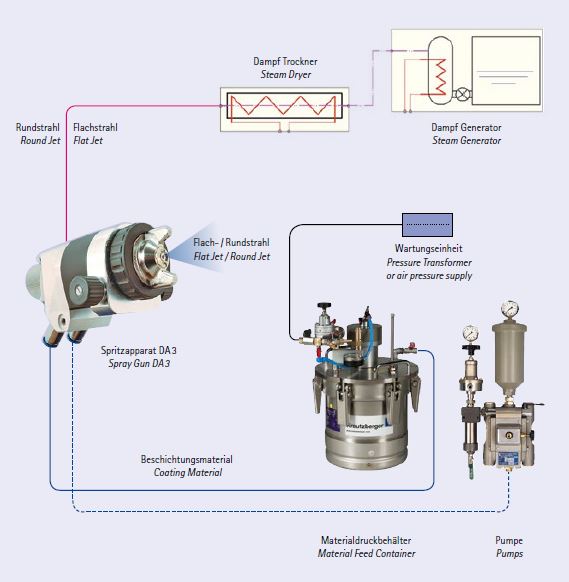

Operation principle

The new and unique steam spraying technology of Krautzberger uses steam instead of compressed air. The coating material is being atomized by steam after leaving the nozzle. The system is already in operation at several coating manufacturers, including manufacturers from the ceramic and sanitary field. The use of steam has many advantages:

Significant reduction of total air consumption

As the atomization is generated by steam, air pressure is solely needed for the feeding of coating material via pump or pressure pot.

Less material consumption

Due to its physical characteristics, the steam ensures a homogeneous and soft application with extreme low bounce back effect.

Shorter drying- and processing time

It sounds paradoxical, but the steam spraying technology leaves less residual moisture on the workpiece and therefore reduces the drying time. This very positive effect leads to reduced waiting periods between coating and drying/firing processes.

Improved working conditions

Lower noise emissions due to reduced atomising pressure. And, less overspray leads to less air pollution for operators and reduces cleaning and maintenance efforts.

Video