Troubleshooting Guide: How to free a seized air motor?

When an air motor is seized then usually due to rust caused by moisture in the air supply. In order to free the motor please follow these instructions. Note: it is necessary to correct the moisture problem and to maintain a dry (but lubricated) air supply. Otherwise the problem will recur.

Step by Step: Free a seized air motor

- Remove any fittings from the air motor inlet and outlet

- Pour penetrating oil into both ports (air inlet and outlet) and allow to soak for 6-12 hours to work

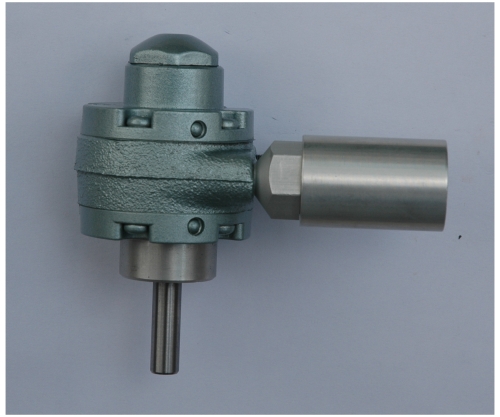

- Gently turn the shaft back and forth with a tool/wrench. To avoid possible damage to the shaft, a coupling can be used in conjunction with the tool (see illustration).

- When the motor is free then run it for several minutes with a dry and lubricated air source. Stop the motor and pour more penetrating lubricant into the motor ports and run the motor again. Repeat this procedure several times until the motor runs smoothly again. Then switch over to detergent SAE #10 oil which should also be used in the air line lubricator under normal conditions.

Compressed Air Requirements

The following compressed air settings should be used for normal operation of the air motor:

- Install an air line filter (5-micron) to remove dirt and moisture

- An automatic air line lubricator should be installed as close as possible to the air line. Set the lubricator to deliver 1 drop of oil (e.g. SAE #10 automotive engine oil) for every 1.4 m3/min (50 CFM) of air while the unit is running. Do not overfeed oil as this may contaminate the exhaust air.